OVERVIEW

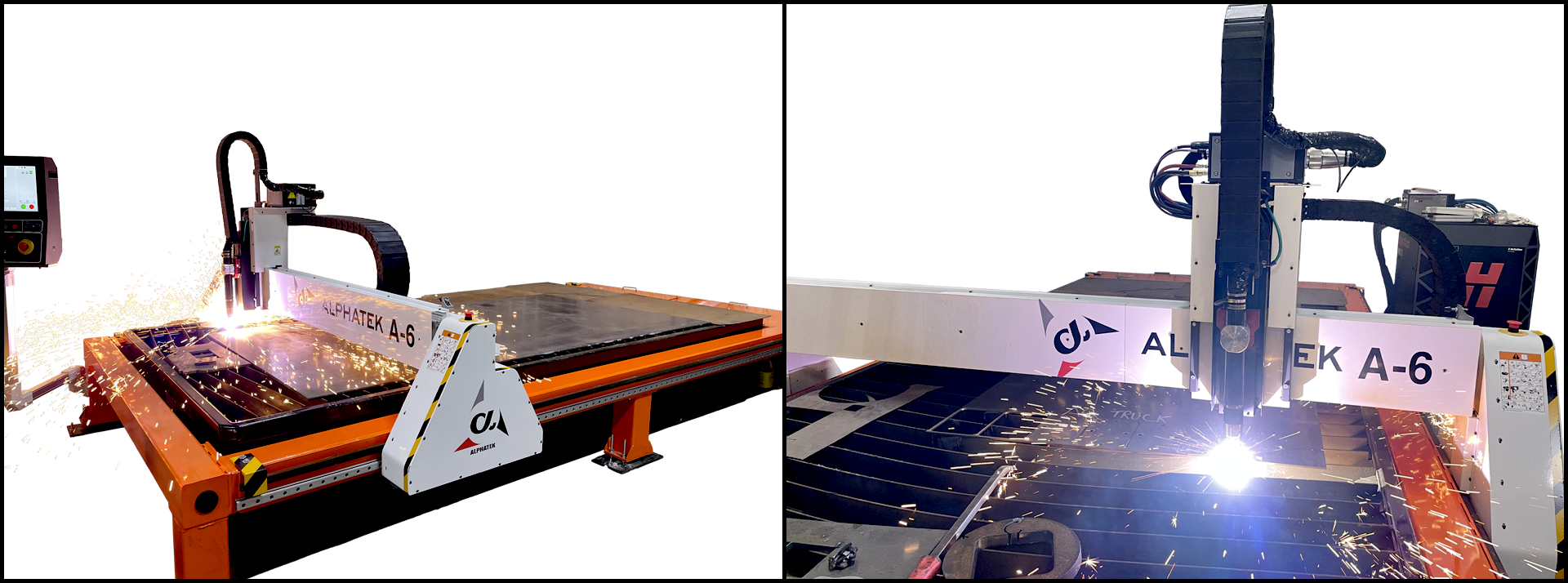

The Alpha Tek A Series cutting machine offers a heavy duty unitized, fully machined bridge design with ultimate accuracy, rugged design and stability. Guides and rack mounting surfaces are machined in a single set-up with Dual Linear Guides & Linear Ways for best accuracy. Linear ways in all (3) Axis; help the system glide smoothly to achieve the best cut quality and optimum motion performance. A lightweight rigid bridge beam is designed for quicker motion response and highest repeatability. A Series machine design allows for additional cost savings for customers wanting to build their own table (water or downdraft). However, Alphatek can also provide a full “turn-key” system with a cutting table (water or downdraft), if needed. The A Series unitized design makes this machine installation quick and makes it easy for relocation in the future.

Our A Series machine is equipped with standard operator assistance tools, such as laser pointer for plate alignment and position finding, plasma station crash sensor and Job/Part recovery in the event of Power Loss or Cut Loss. A Series machine operating and plasma cutting system can be configured with Hypertherm “True-Hole” ® or Lincoln Electric Ultra Sharp 2.0® cutting technology. In addition, with the purchase of an A Series machine, Alpha Tek provides free phone and remote assistance support for the life of the machine.

Our A Series machine is equipped with standard operator assistance tools, such as laser pointer for plate alignment and position finding, plasma station crash sensor and Job/Part recovery in the event of Power Loss or Cut Loss. A Series machine operating and plasma cutting system can be configured with Hypertherm “True-Hole” ® or Lincoln Electric Ultra Sharp 2.0® cutting technology. In addition, with the purchase of an A Series machine, Alpha Tek provides free phone and remote assistance support for the life of the machine.